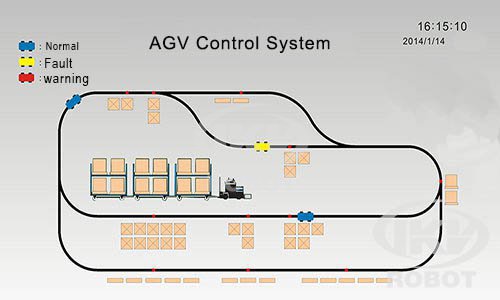

AGV control system

Release date: 2016-08-05 17:49 Clicks: Author: admin

AGV control system Introduction

Automated Guided Vehicle (AGV) Controls can lower labor costs and increase productivity for industrial users. AGV control system include system configuration, key modules task management, congestion control, and real-time monitoring. AGV Controls can cooperative control and management, task scheduling, tasks, calls and device interface with ERP, WMS and PLC. AGVS intelligent is an important part of the logistics system. TheAGV system is an essential part of the automated guided vehicle system, with the main task being to control the AGVs' traffic flow.

AGV control system modules

a. map management function

1, Automated Guided Vehicle (AGV) Controls support editing and configuration path, multi-AGV centralized distribution path;

2, magnetic navigation AGV support RFID landmark definition, and supports multipath portfolio allocation issued;

3, inertial navigation map AGV support CAD import, custom calibration points, auto-generated running path;

b. dynamic task management

1, Automated Guided Vehicle (AGV) Controls supports automatic tasks issued, or production and ERP software can exchange data, automatic distribution transport task;

2, Automated Guided Vehicle (AGV) Controls supports manual assignments, assign specific tasks to the transport destination;

3, Automated Guided Vehicle (AGV) Controls support the call feature on-demand stations, traffic control software dynamic allocation of AGV completed the transport of goods to the designated station;

c. Multi-AGV Configure Distribution

1, AGV control system supports multi-AGV management, centralized configuration parameters support software distribution;

2, a powerful path editing function, multi-path can be defined as a combination of tasks;

3, support for remote control software AGV car upgrades and troubleshooting capabilities, and easier to maintain;

d. Rich interface and extended functionality

1, I / O modules can be defined, user-defined events and actions;

2, AGV control system support and PLC interface, auto-complete material unloading dock;

3, wireless pager, click to call AGV to the station;

4, support for ERP and WMS data exchange, automatic generation transport task;

5, support the Tablet PC control, automatic or manual mode;

e. Congestion control and avoidance management

AGV control system benefits

1, supports a variety of AGV navigation work;

2, supports dynamic call tasks manually assigned tasks, and automatically issued a mandate;

3, real-time display AGV running, and can be abnormal alarm;

4, online software upgrades, AGV system embedded control system can also be upgraded online;

5, can automatically PLC and other automation equipment interface actions, and events;

6, can provide actions and tasks for the upper software calls and queries.

AGV control system parameters

|

characteristic |

Specifications |

Descipition |

|

Operating Environment

|

Service-Terminal

|

Windows 2003/2008 SERVER |

|

Client-side

|

WinXP/Win7/Win2008 |

|

mobile client-side

|

Android 4.0 and above |

|

Support Database

|

Mysql server |

Support

|

|

SQLserver 2000 |

Support

|

|

Map formats

|

YAML format |

Support

|

|

CAD format |

Support

|

|

Protocol

|

TCP/IP WIFI |

Support

|

|

Zigbe agareement |

Support

|

|

Call terminal

|

Phone or tablet

|

Support

|

|

433MH Call button |

Support

|

|

Software maintenance

|

Multi-AGV batch configuration distribution

|

Support

|

|

Online software upgrade

|

Support

|

|

Statistics report format

|

EXCEL or TXT |

|

VPN Virtual network access |

Support

|

[close]

[print]

[back]

[forward]

[refresh]